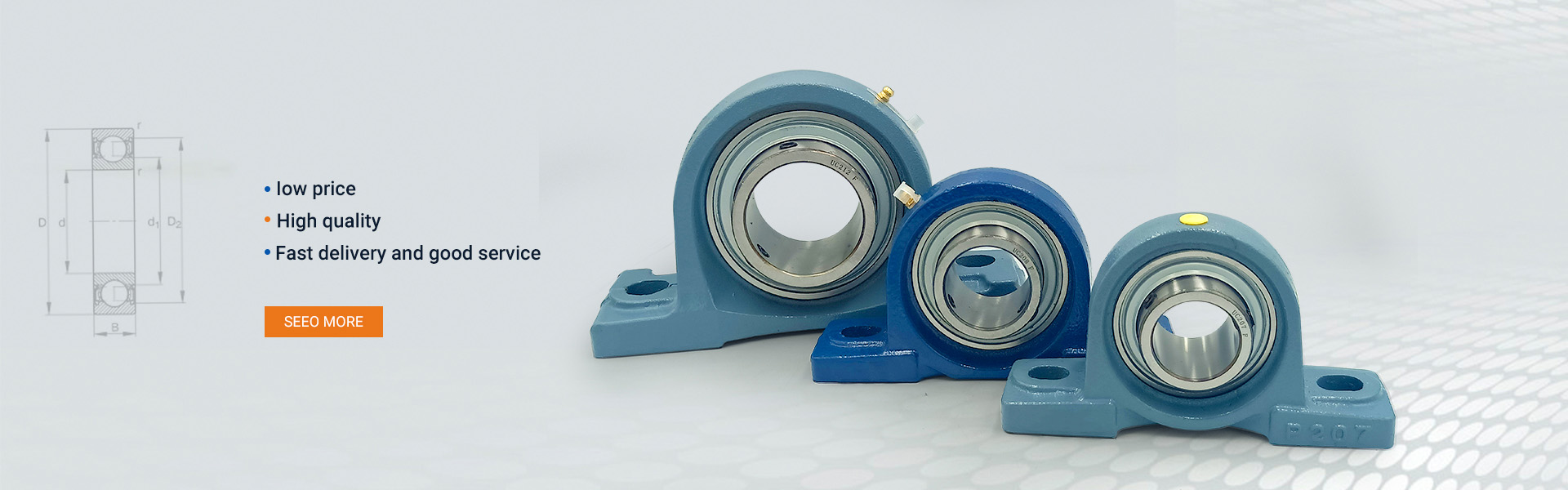

UCP Bearings: The Core Support for Industrial Power Transmission,

,

| |

UC BEARING Size (mm) |

BLOCK(housing)Size (mm) |

|

| MODEL |

lnner ring |

Outer ring |

lnner ring height |

width |

length |

height |

Hole distance |

weight Kg |

| UCP214F |

70 |

125 |

74.6 |

73.3 |

264 |

157 |

210 |

6.3 |

| Revolutions per minute |

| limit |

7000 rev |

| Warranty |

1500 rev |

| Accessory grade |

| Grease |

LOW-20 HIGH+250 |

| Ball |

G8 |

| Material |

Gcr15 |

| Cage |

Lenient |

| Block naterial |

HT200 |

| Sealing ring |

F Contact type, dustproof, waterproof |

Basic Definition & Structural Features

Basic Definition & Structural Features

UCP bearings (Pillow Block Bearings with Insert) are pre-assembled units comprising a bearing insert housed within a cast iron or pressed steel pedestal. Key characteristics include:

• Spherical Outer Surface: The bearing outer diameter features a spherical design, enabling ±3° self-aligning capability.

• Pre-sealed Configuration: Standard rubber seals (RS or 2RS configuration) provide IP54-rated protection against dust and water ingress.

• Standardized Housing: Compliant with ISO 113:2015, ensuring cross-brand interchangeability of mounting hole spacing.

2. Operating Principles & Mechanical Properties

2.1 Load Transmission Mechanism

Load transfer occurs through rolling elements (steel balls) between inner and outer rings:

• Radial Loads: Transmitted along the bearing radius (accounting for ~70% of load capacity).

• Axial Loads: Accommodate unidirectional axial forces (≈20% of radial load capacity).

2.2 Tribological Properties

• Ultra-low rolling friction coefficient: 0.001–0.003

• Maximum speed: 3,000 rpm with lithium-based grease lubrication (2,000-hour grease life @ 70°C).

3. Typical Application Scenarios

3.1 Agricultural Machinery

• Combine harvester drive shafts (operating temp.: -30°C to 80°C)

• Irrigation system worm gear reducers (require anti-corrosion coatings)

3.2 Food Processing Industry

• Conveyor belt drive units (FDA-compliant stainless steel variants)

• Crank mechanisms in packaging machines (withstanding cyclic shock loads)

3.3 Mining Equipment

• Vibrating screens in crushers (require supplemental labyrinth seals)

• Belt conveyor idler rollers (special lubrication solutions for dusty environments)

4. Technical Selection Guidelines

Bearing Unit No. Dimensions (in.)or(mm) Bolt Used mm/in. Bearing No. Weight(kg)

d h a e b s1

UCP214 70 79.4 266 210 72 25 M20 UC214 6.3

UCP214-42 2-5/8 3-1/8 10-15/32 8-17/64 2-27/32 63/64 3/4 UC214-42 6.3

UCP214-43 2-11/16 3-1/8 10-15/32 8-17/64 2-27/32 63/64 3/4 UC214-43 6.3

UCP214-44 2-3/4 3-1/8 10-15/32 8-17/64 2-27/32 63/64 3/4 UC214-44 6.3

Previous:

UCP Bearings: The Core Support for Industrial Power Transmission

Next:

UCP Bearings: The Core Support for Industrial Power Transmission

Basic Definition & Structural Features

Basic Definition & Structural Features