Welcome to our websites!

-

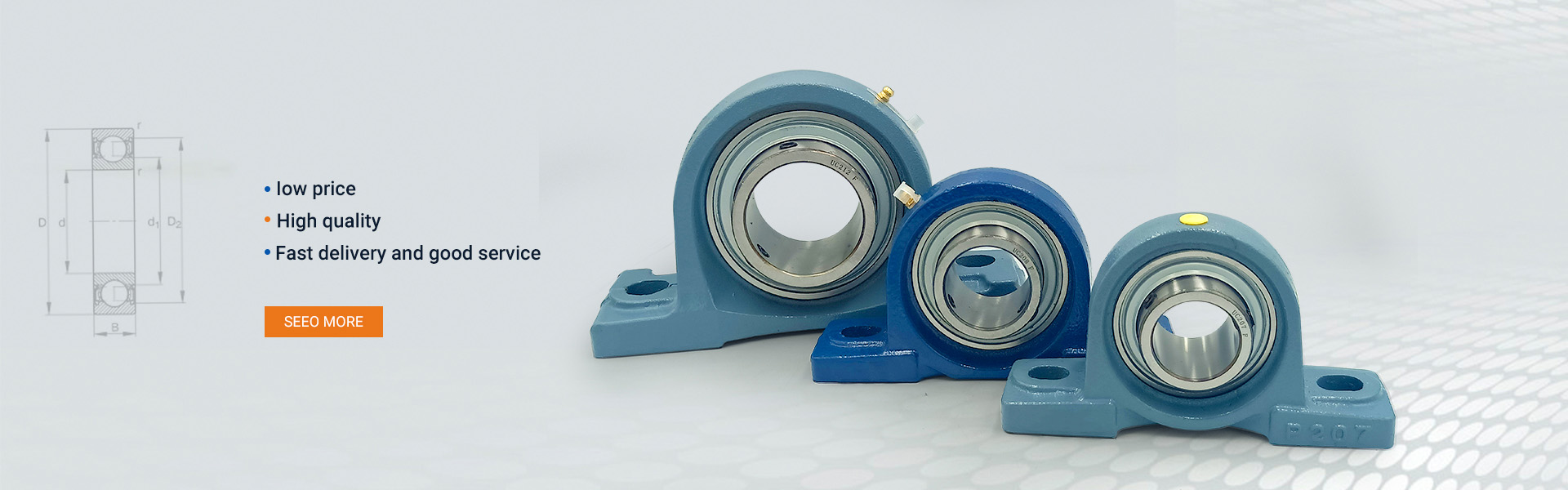

ODM Manufacturer High Quality Bearing Units /Bearing Housings/ Pillow Block Bearings

The outer ring of the UCP bearing features a spherical design that mates with the concave surface of the bearing housing. This structure enables the compensation of axial misalignment within a range of 0.5° to 2°, thereby accommodating various installation conditions. The integrated construction simplifies the assembly process and allows for individual replacement of bearing components during maintenance, thus reducing both maintenance time and associated costs. The double-sided contact seal effectively prevents dust ingress, making the bearing suitable for use in dusty environments. Additionally, the UCP bearing is capable of operating reliably under temperatures ranging from -30°C to 120°C, which ensures its applicability in high-speed and heavy-load applications. -

Professional China Bearing Rodamientos Thrust Ball Bearing Ucpa206 Pillow Block Bearing for Agricultural Machinery Cast with Iron Units

The outer ring of the UCP bearing features a spherical design that mates with the concave surface of the bearing housing. This structure enables the compensation of axial misalignment within a range of 0.5° to 2°, thereby accommodating various installation conditions. The integrated construction simplifies the assembly process and allows for individual replacement of bearing components during maintenance, thus reducing both maintenance time and associated costs. The double-sided contact seal effectively prevents dust ingress, making the bearing suitable for use in dusty environments. Additionally, the UCP bearing is capable of operating reliably under temperatures ranging from -30°C to 120°C, which ensures its applicability in high-speed and heavy-load applications. -

Professional Factory for Fkl NSK/NTN/Koyo Pillow Block Bearing House Bearing UCP Ucf UCFL Ucfc UCT Ucpa Ucfa Ucfb Ucph Bearing Units with Insert Bearing Open End Spinning Bearing

The outer ring of the UCP bearing features a spherical design that mates with the concave surface of the bearing housing. This structure enables the compensation of axial misalignment within a range of 0.5° to 2°, thereby accommodating various installation conditions. The integrated construction simplifies the assembly process and allows for individual replacement of bearing components during maintenance, thus reducing both maintenance time and associated costs. The double-sided contact seal effectively prevents dust ingress, making the bearing suitable for use in dusty environments. Additionally, the UCP bearing is capable of operating reliably under temperatures ranging from -30°C to 120°C, which ensures its applicability in high-speed and heavy-load applications. -

High definition China NSK NTN Fyh 4 Bolts Pillow Block Bearing UCP204 UCP205 UCP206 UCP208 UCP209 UCP210 UCP212 UCP214 for Agricultural Machinery

The outer ring of the UCP bearing features a spherical design that mates with the concave surface of the bearing housing. This structure enables the compensation of axial misalignment within a range of 0.5° to 2°, thereby accommodating various installation conditions. The integrated construction simplifies the assembly process and allows for individual replacement of bearing components during maintenance, thus reducing both maintenance time and associated costs. The double-sided contact seal effectively prevents dust ingress, making the bearing suitable for use in dusty environments. Additionally, the UCP bearing is capable of operating reliably under temperatures ranging from -30°C to 120°C, which ensures its applicability in high-speed and heavy-load applications. -

Product Introduction: UCF209 Pillow Block Bearing by VPN Pride Bearing

The Pillow Block Bearing UCF209 is a spherical plain bearing unit with a housing. The core is the UC209 ball bearing (1-5/8-inch inner diameter), pre-assembled in a sturdy cast iron square housing. The base is equipped with four bolt holes for easy installation and fixation. It is designed to support rotating shafts, providing reliable support and is suitable for general industrial applications such as conveyors and agricultural machinery. -

Product Introduction: UCF208 Pillow Block Bearing by VPN Pride Bearing

The Pillow Block Bearing UCF208 is a spherical plain bearing unit with a housing. The core is the UC208 ball bearing (1-1/2-inch inner diameter), pre-assembled in a sturdy cast iron square housing. The base is equipped with four bolt holes for easy installation and fixation. It is designed to support rotating shafts, providing reliable support and is suitable for general industrial applications such as conveyors and agricultural machinery. -

Product Introduction: UCF207 Pillow Block Bearing by VPN Pride Bearing

The outer ring of the UCP bearing features a spherical design that mates with the concave surface of the bearing housing. This structure enables the compensation of axial misalignment within a range of 0.5° to 2°, thereby accommodating various installation conditions. The integrated construction simplifies the assembly process and allows for individual replacement of bearing components during maintenance, thus reducing both maintenance time and associated costs. The double-sided contact seal effectively prevents dust ingress, making the bearing suitable for use in dusty environments. Additionally, the UCP bearing is capable of operating reliably under temperatures ranging from -30°C to 120°C, which ensures its applicability in high-speed and heavy-load applications. -

Product Introduction: UCF206 Pillow Block Bearing by VPN Pride Bearing

The Pillow Block Bearing UCF206 is a spherical plain bearing unit with a housing. The core is the UC206 ball bearing (1-1/16-inch inner diameter), pre-assembled in a sturdy cast iron square housing. The base is equipped with four bolt holes for easy installation and fixation. It is designed to support rotating shafts, providing reliable support and is suitable for general industrial applications such as conveyors and agricultural machinery. -

Product Introduction: UCF205 Pillow Block Bearing by VPN Pride Bearing

The Pillow Block Bearing UCF205 is a spherical plain bearing unit with a housing. The core is the UC205 ball bearing ( 13/16-inch inner diameter), pre-assembled in a sturdy cast iron square housing. The base is equipped with four bolt holes for easy installation and fixation. It is designed to support rotating shafts, providing reliable support and is suitable for general industrial applications such as conveyors and agricultural machinery. -

Product Introduction: UCF204 Pillow Block Bearing by VPN Pride Bearing

The Pillow Block Bearing UCF204 is a spherical plain bearing unit with a housing. The core is the UC204 ball bearing ( 3/4-inch inner diameter), pre-assembled in a sturdy cast iron square housing. The base is equipped with four bolt holes for easy installation and fixation. It is designed to support rotating shafts, providing reliable support and is suitable for general industrial applications such as conveyors and agricultural machinery. -

Lowest Price for Bearing Miniature Ball Bearing/Auto Parts Bearing/Pillow Block Bearing Low Price 6205 6206 6208 Deep Groove Ball Bearing

The outer ring of the UCP bearing features a spherical design that mates with the concave surface of the bearing housing. This structure enables the compensation of axial misalignment within a range of 0.5° to 2°, thereby accommodating various installation conditions. The integrated construction simplifies the assembly process and allows for individual replacement of bearing components during maintenance, thus reducing both maintenance time and associated costs. The double-sided contact seal effectively prevents dust ingress, making the bearing suitable for use in dusty environments. Additionally, the UCP bearing is capable of operating reliably under temperatures ranging from -30°C to 120°C, which ensures its applicability in high-speed and heavy-load applications. -

Factory For Pillow Block Bearing Insert Bearing Heavy Duty Ball Insert Bearing Housing Ball Bearing Smn200kb Smn201kb Smn202kb Smn203kb Smn204kb

The outer ring of the UCP bearing features a spherical design that mates with the concave surface of the bearing housing. This structure enables the compensation of axial misalignment within a range of 0.5° to 2°, thereby accommodating various installation conditions. The integrated construction simplifies the assembly process and allows for individual replacement of bearing components during maintenance, thus reducing both maintenance time and associated costs. The double-sided contact seal effectively prevents dust ingress, making the bearing suitable for use in dusty environments. Additionally, the UCP bearing is capable of operating reliably under temperatures ranging from -30°C to 120°C, which ensures its applicability in high-speed and heavy-load applications.